What is the Difference Between Smd Inductor and Wirewound Inductor?

Surface Mount Inductor (SMI) and Wire-Wound Inductor are both commonly used inductors in electronic components, but they have certain differences in structure and performance.

1. Structure of Smd inductor and wire wound inductor

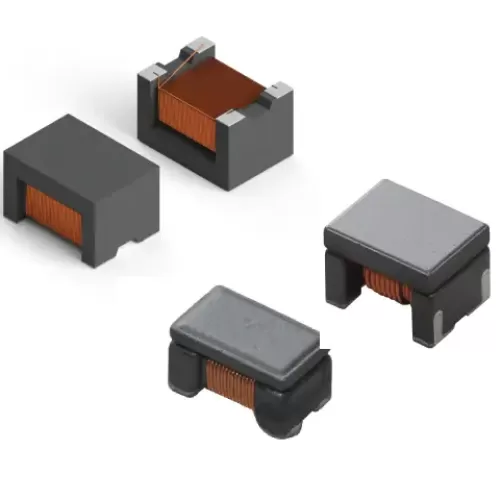

The structure of Smd inductor is relatively simple, usually consisting of a magnetic core and wires wound on the chip. Wirewound inductors require wire or foil to be wound by hand or machine and then fixed on the magnetic core. Therefore, relative to Smd inductors, wirewound inductors are more complex in the manufacturing process.

SM Series SMD Unshielded Power Inductors

SMRH1 Series SMD Shielded Power Inductors

2. Performance of Smd inductor and wirewound inductor

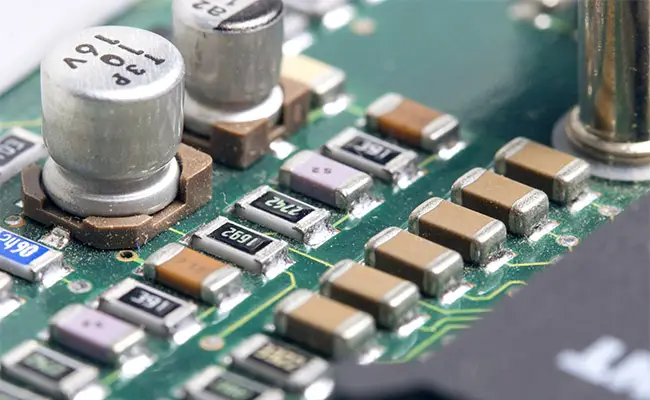

The performance of Smd inductors and wirewound inductors are also different. For example, the DC resistance of Smd inductors is small and the self-resonant frequency point is high; while the DC resistance of wire-wound inductors is large and the self-resonant frequency point is low. In addition, due to its compact structure, Smd inductors can achieve high-density layout and are suitable for miniaturization and lightweight equipment; wire-wound inductors are suitable for high-power and high-frequency applications.

3. Application of Smd inductor and wire wound inductor

Smd inductors are usually used in small electronic devices such as mobile phones, MP3s, and PDAs, and are also widely used in automotive electronics, medical equipment, aerospace and other fields. Wirewound inductors are widely used in power supplies, converters, filters, regulators and other fields. Due to their different performance, the two inductor components have their own advantages and are selected and used according to different application scenarios.

Offering a wide range of SMD inductors, we at Zxcompo are a reliable inductor manufacturer that can meet your specific needs. Contact us for samples: sales@ZXcompo.com.