Both plug-in three-pin inductors and SMD three-pin inductors are widely used. Due to their different product structures, manufacturing processes, and raw materials, their characteristics are quite different.

First, let’s talk about the obvious advantages of SMD three-pin inductors over plug-in three-pin inductors, especially in the design and production of modern electronic products.

The advantages of SMD three-pin inductors over plug-in three-pin inductors are as follows:

Save Space: SMD three-pin inductors can be placed directly on the PCB board to save circuit board space, which is particularly important for the design of electronic products with limited space.

Reduce Costs: SMD three-pin inductors are usually packaged in discs and can be directly put on the machine for automated production without manual plug-in, thereby reducing labor costs.

Improve Production Efficiency: SMD inductors can arrange components on both sides to improve welding efficiency, while plug-in inductors require a larger space and may require more manual operations.

Improve Product Performance: SMD inductors have no pins, which can reduce parasitic capacitance, improve the performance of the product itself, and greatly improve the quality of the product.

Strong Adaptability: The height of SMD three-pin inductors is consistent with that of ordinary SMD inductors, which is suitable for products in all application fields, while the height of plug-in three-pin inductors is fixed, and the product volume must be larger.

Although plug-in three-pin inductors may have certain advantages in cost, especially when a lot of manpower is required, with the popularization of automated production lines and the reduction of costs, the advantages of SMD three-pin inductors are becoming more and more obvious. Therefore, for most modern electronic product designs, SMD three-pin inductors are a better choice.

(★ If you want to know more information, check out more: • Electronic Components: Introduction to the Principle of Three-Pin Inductor)

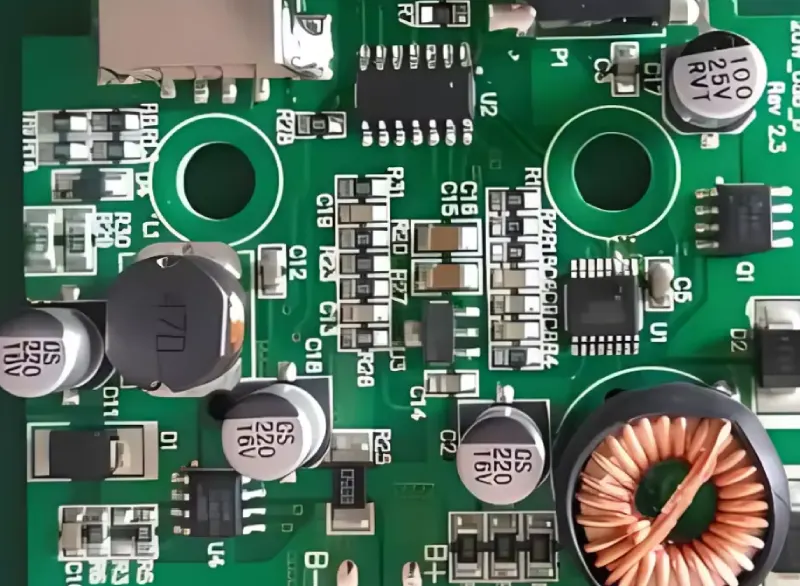

The following is an example of replacing a plug-in three-pin inductor with a SMD three-pin inductor:

1. Project Case Background

One of our customers is engaged in the production and processing of buzzer products and has been using a certain brand of three-pin plug-in inductors. However, due to the recent iteration and upgrade of its products, the design has undergone fundamental changes compared to the past, rather than a single upgrade of one party.

In this product iteration and upgrade, the customer will directly use a three-pin SMD inductor to replace the plug-in three-pin inductor that has been used. In addition to changing the inductor application solution, the circuit board design has also changed greatly. The entire circuit board has been redesigned, and the overall size of the board has been further reduced, which will completely break the previous circuit board layout structure.

In this product iteration and upgrade, the customer originally planned to continue to use the inductor solution of the original plug-in three-pin inductor supplier, but the original supplier could not provide corresponding technical and product solution support. Since ZXcompo has rich experience in inductor customization and conventional inductor upgrades, the customer contacted us to provide corresponding support in this regard.

2. Customer project application requirements

In this project case, the customer’s inductor application requirements mainly come from the redesign of the circuit board. The original circuit board size specifications are further reduced, resulting in the original plug-in three-pin inductor application solution being unable to meet the current new design requirements, and other inductors are needed as new solutions.

After comprehensive consideration, it was decided to choose the SMD three-pin inductor as the new inductor solution. Therefore, our company needs to provide a practical SMD three-pin inductor application solution based on the current new needs.

3. Application Solution

In response to the customer’s current new inductor needs, our company has adopted an existing SMD inductor that fully matches the customer’s current inductor usage needs in terms of electrical performance, but the package size is too large to be successfully installed on the newly designed circuit board.

Our company’s technical department has improved the current production process of SMD inductors and further optimized and adjusted the powder formula of this SMD inductor. The trial-produced 2K SMD three-pin inductor has been sent to the customer for board inspection. The test decibel number fully meets the 90 limit requirements in the customer’s case. The entire test is flawless and 100% passed the test.

In response to the customer’s requirement to increase margin, the company’s technical department has put forward improvement and optimization suggestions for the customer’s circuit board design, optimized the design of the current new circuit board, and met the customer’s requirement to increase margin.

4. Basic electrical properties of SMD three-pin inductor products

| Product type: | SMD three-pin inductor |

| Inductance accuracy: | 600uH:25mH±20% |

| Resistance: | 1-2 pin resistance 4.79-4.94Ω, 2-3 pin resistance 44.8-46Ω |

| Current size: | / |

| Package specification: | 7.7 * 7.8 * 6.3 |

| Special process: | very thin wire, winding process |