1. The Importance and role of Inductors in electronic product design

Inductors play a crucial role in electronic product design, as they are essential components for achieving performance optimization and circuit stability. Here, we will introduce the importance and role of inductors in electronic product design.

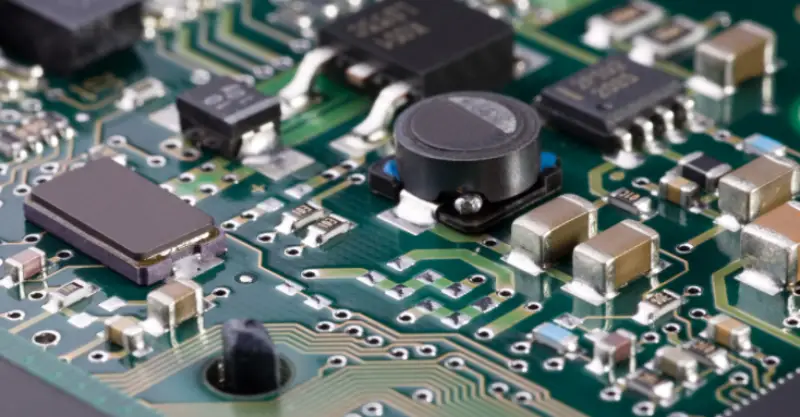

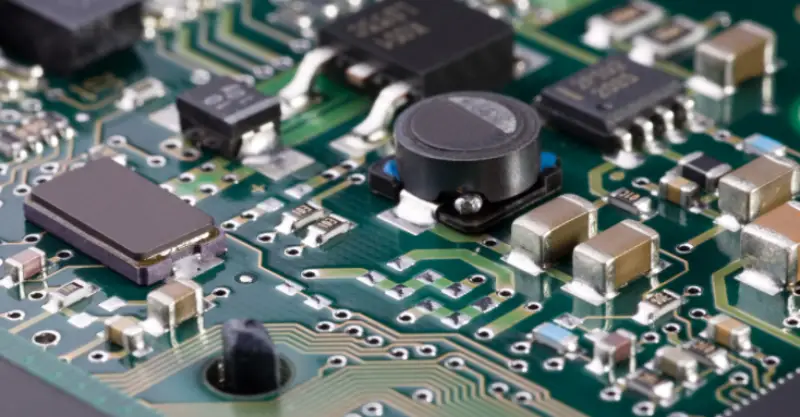

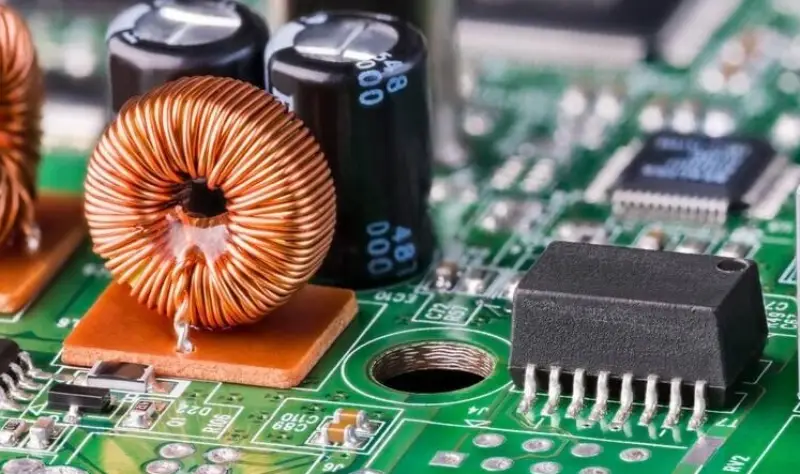

Inductors are passive components that store energy by inducing a magnetic field. They are primarily composed of coils, typically formed by winding conductive wires into a spiral shape, which generates a magnetic field. In electronic product design, inductors serve the following important functions:

Filtering and noise suppression: Inductors can be used as key components in filters to remove unwanted noise and interference from signals. By selecting appropriate inductance values and frequency responses, inductors can block specific frequencies, thereby improving signal purity and accuracy.

Voltage regulation and current stabilization: Inductors play a vital role in voltage regulation and current stabilization. In DC-DC converters, for instance, inductors are used to store and smooth out currents, ensuring a stable output voltage. They can also suppress current surges and ripples, providing a stable power supply to other circuit modules.

Energy transfer and transmission: Inductors are crucial for wireless charging and energy transfer applications. By directing current into the coil, inductors generate a magnetic field that couples with other coils, enabling energy transfer and transmission. This wireless energy transfer technology finds wide application in wireless charging, inductive communication, and electric vehicle charging.

Circuit and component protection: Inductors can be employed to protect circuits and components from current surges and overvoltages. They play a vital role in suppressing overcurrent and limiting voltage peaks, ensuring the safe operation of other electronic elements.

Frequency selection and tuning: Inductors are utilized for selecting specific frequencies and tuning signals. In communication systems, inductors are used to choose particular frequency bands, achieving frequency selection and filtering to enhance signal quality and reliability.

In conclusion, the importance of inductors in electronic product design cannot be overstated. They play critical roles in filtering, voltage regulation, energy transfer, circuit protection, and frequency tuning, contributing to enhanced performance and reliability. Correct selection and application of inductors are crucial for engineers and designers to achieve optimized electronic product designs.

2. The basic principle and working mechanism of the inductor

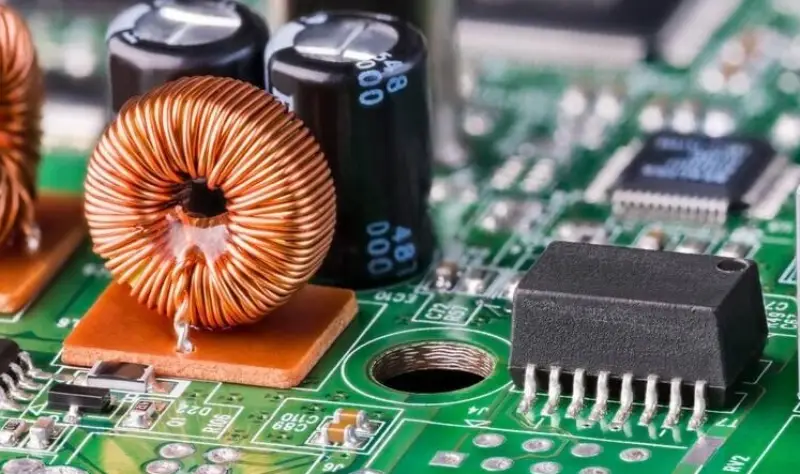

Inductors are fundamental electronic components that operate based on the principle of generating a magnetic field through the flow of current in a coil and inducing an electromotive force (EMF) when the magnetic field changes. The basic structure of an inductor typically consists of a coil made of wound conductive wire.

The working principle of an inductor is based on Faraday’s law of electromagnetic induction. When current flows through the coil of an inductor, a magnetic field is generated, with the strength of the magnetic field proportional to the current. Additionally, when the current changes, the magnetic field also changes, resulting in the induction of an electromotive force (EMF) in the inductor. This induced EMF opposes the change in current, demonstrating the inductive nature of the inductor.

Inductors have the ability to store energy. As current flows through the coil, the inductor converts a portion of the current’s energy into magnetic field energy, storing it in the magnetic field. When the current is interrupted or changes, the energy stored in the magnetic field is released back into the coil, converting it into electrical energy, thereby maintaining the continuity and stability of the current.

Furthermore, inductors can generate a magnetic field. The magnetic field produced by the current flowing through the coil can be utilized in various applications, such as wireless power transfer, motor drive systems, and electromagnetic induction.

Inductors also respond to changes in current. When there is a variation in current in the circuit connected to the inductor, the inductor generates an induced EMF based on Faraday’s law of electromagnetic induction, resulting in self-induced voltage. This self-induced voltage affects the voltage and current distribution within the circuit, influencing the performance and behavior of the circuit.

3. The impact of correct selection on performance and reliability

The correct selection of inductors has a significant impact on their performance and reliability. Here are some key parameters and indicators, along with their importance, as well as how to choose the appropriate type and specifications of inductors based on application requirements:

Inductance: Inductance is an important parameter that measures the size of an inductor. It determines the inductor’s ability to store energy. A larger inductance value can store more energy but may result in a larger size and cost. Therefore, a trade-off between inductance value and size needs to be considered based on application requirements.

Saturation Current: Saturation current is the maximum current that an inductor can withstand. Exceeding the saturation current may result in a weakened magnetic field, affecting the performance of the inductor. It is crucial to choose an inductor with a saturation current sufficient for the maximum current demand of the application.

Frequency Response: Frequency response indicates the performance of an inductor at different frequencies. For a specific application, the frequency response range and attenuation characteristics of the inductor need to be considered. Ensuring that the inductor meets the performance requirements within the desired frequency range is important.

Inductor Type: Selecting the appropriate type of inductor based on application requirements is essential, such as ferrite inductors, air core inductors, chip inductors, etc. Each type has different characteristics, such as inductance range, current handling capability, and size.

Special Requirements: Some applications may have specific requirements for inductors, such as temperature stability, moisture resistance, vibration resistance, etc. These special requirements need to be considered when selecting an inductor to ensure its performance and reliability in specific environments.

By carefully evaluating application requirements and understanding the importance of key parameters, it is possible to choose the appropriate type and specifications of inductors to achieve optimized performance and reliability.

4. Considerations and best practice recommendations when Designing inductor applications

When designing applications involving inductors, here are some considerations and best practices to emphasize the importance of good layout, proper heat dissipation, and protective measures, as well as how to conduct testing and verification to ensure the performance and reliability of the inductors meet expectations.

Good layout and coil design: Place the inductors as far as possible from other sources of high-frequency interference to reduce electromagnetic interference. Also, layout the coils appropriately, avoiding cross-interference between coils and between coils and other components.

Heat dissipation design: Inductors generate heat during operation, so proper heat dissipation measures such as heat sinks, heat plates, or fans should be provided. Maintaining the inductors within a safe temperature range improves their reliability and lifespan.

Protective measures: Consider implementing appropriate protection measures based on application requirements, such as overcurrent protection, over-temperature protection, and overvoltage protection. These measures help prevent damage to the inductors under abnormal conditions.

Perform reliability testing: Rigorous reliability testing is crucial once the design is completed. The testing process can include temperature testing, vibration testing, voltage stress testing, etc., to validate the performance and reliability of the inductors under different environments and operating conditions.

Verify inductor parameters: Validate key parameters of the inductors such as inductance, saturation current, frequency response, etc. Use suitable measurement equipment and methods to ensure that the inductor parameters align with expectations.

Consider environmental factors: Understand the environmental conditions in which the inductors will be operating and select appropriate materials and coatings. This provides additional protection and enhances the reliability of the inductors.

Document records: Maintain detailed documentation of the inductor design and testing processes, including parameters, layout, heat dissipation design, protective measures, etc. This facilitates traceability, troubleshooting, and serves as a reference for future designs.

By following these considerations and best practices, the performance and reliability of inductor applications can be improved, ensuring they meet the desired design requirements.

Summary

The key takeaway of this article is the emphasis on the importance of inductors in improving the performance and reliability of electronic product design. As essential components, inductors serve various functions and roles. Proper selection of inductors, optimization of layout, adequate heat dissipation, protective measures, as well as reliability testing and verification, are critical steps to ensure the expected performance and reliability of inductors. By effectively applying inductors, electronic products can benefit from improved filtering, voltage regulation, energy transfer, and protection capabilities, enhancing system efficiency, stability, and overall lifespan.

ZXcompo is a manufacturing company specializing in custom inductors, capacitors, resistors, and more. Find high-quality passive electronic components for your projects. If you have product needs and inquiries. Please contact us now:

sales@ZXcompo.com

Inductors are passive components that store energy by inducing a magnetic field. They are primarily composed of coils, typically formed by winding conductive wires into a spiral shape, which generates a magnetic field. In electronic product design, inductors serve the following important functions:

Filtering and noise suppression: Inductors can be used as key components in filters to remove unwanted noise and interference from signals. By selecting appropriate inductance values and frequency responses, inductors can block specific frequencies, thereby improving signal purity and accuracy.

Voltage regulation and current stabilization: Inductors play a vital role in voltage regulation and current stabilization. In DC-DC converters, for instance, inductors are used to store and smooth out currents, ensuring a stable output voltage. They can also suppress current surges and ripples, providing a stable power supply to other circuit modules.

Energy transfer and transmission: Inductors are crucial for wireless charging and energy transfer applications. By directing current into the coil, inductors generate a magnetic field that couples with other coils, enabling energy transfer and transmission. This wireless energy transfer technology finds wide application in wireless charging, inductive communication, and electric vehicle charging.

Circuit and component protection: Inductors can be employed to protect circuits and components from current surges and overvoltages. They play a vital role in suppressing overcurrent and limiting voltage peaks, ensuring the safe operation of other electronic elements.

Frequency selection and tuning: Inductors are utilized for selecting specific frequencies and tuning signals. In communication systems, inductors are used to choose particular frequency bands, achieving frequency selection and filtering to enhance signal quality and reliability.

In conclusion, the importance of inductors in electronic product design cannot be overstated. They play critical roles in filtering, voltage regulation, energy transfer, circuit protection, and frequency tuning, contributing to enhanced performance and reliability. Correct selection and application of inductors are crucial for engineers and designers to achieve optimized electronic product designs.

Inductors are passive components that store energy by inducing a magnetic field. They are primarily composed of coils, typically formed by winding conductive wires into a spiral shape, which generates a magnetic field. In electronic product design, inductors serve the following important functions:

Filtering and noise suppression: Inductors can be used as key components in filters to remove unwanted noise and interference from signals. By selecting appropriate inductance values and frequency responses, inductors can block specific frequencies, thereby improving signal purity and accuracy.

Voltage regulation and current stabilization: Inductors play a vital role in voltage regulation and current stabilization. In DC-DC converters, for instance, inductors are used to store and smooth out currents, ensuring a stable output voltage. They can also suppress current surges and ripples, providing a stable power supply to other circuit modules.

Energy transfer and transmission: Inductors are crucial for wireless charging and energy transfer applications. By directing current into the coil, inductors generate a magnetic field that couples with other coils, enabling energy transfer and transmission. This wireless energy transfer technology finds wide application in wireless charging, inductive communication, and electric vehicle charging.

Circuit and component protection: Inductors can be employed to protect circuits and components from current surges and overvoltages. They play a vital role in suppressing overcurrent and limiting voltage peaks, ensuring the safe operation of other electronic elements.

Frequency selection and tuning: Inductors are utilized for selecting specific frequencies and tuning signals. In communication systems, inductors are used to choose particular frequency bands, achieving frequency selection and filtering to enhance signal quality and reliability.

In conclusion, the importance of inductors in electronic product design cannot be overstated. They play critical roles in filtering, voltage regulation, energy transfer, circuit protection, and frequency tuning, contributing to enhanced performance and reliability. Correct selection and application of inductors are crucial for engineers and designers to achieve optimized electronic product designs.

Good layout and coil design: Place the inductors as far as possible from other sources of high-frequency interference to reduce electromagnetic interference. Also, layout the coils appropriately, avoiding cross-interference between coils and between coils and other components.

Heat dissipation design: Inductors generate heat during operation, so proper heat dissipation measures such as heat sinks, heat plates, or fans should be provided. Maintaining the inductors within a safe temperature range improves their reliability and lifespan.

Protective measures: Consider implementing appropriate protection measures based on application requirements, such as overcurrent protection, over-temperature protection, and overvoltage protection. These measures help prevent damage to the inductors under abnormal conditions.

Perform reliability testing: Rigorous reliability testing is crucial once the design is completed. The testing process can include temperature testing, vibration testing, voltage stress testing, etc., to validate the performance and reliability of the inductors under different environments and operating conditions.

Verify inductor parameters: Validate key parameters of the inductors such as inductance, saturation current, frequency response, etc. Use suitable measurement equipment and methods to ensure that the inductor parameters align with expectations.

Consider environmental factors: Understand the environmental conditions in which the inductors will be operating and select appropriate materials and coatings. This provides additional protection and enhances the reliability of the inductors.

Document records: Maintain detailed documentation of the inductor design and testing processes, including parameters, layout, heat dissipation design, protective measures, etc. This facilitates traceability, troubleshooting, and serves as a reference for future designs.

By following these considerations and best practices, the performance and reliability of inductor applications can be improved, ensuring they meet the desired design requirements.

Good layout and coil design: Place the inductors as far as possible from other sources of high-frequency interference to reduce electromagnetic interference. Also, layout the coils appropriately, avoiding cross-interference between coils and between coils and other components.

Heat dissipation design: Inductors generate heat during operation, so proper heat dissipation measures such as heat sinks, heat plates, or fans should be provided. Maintaining the inductors within a safe temperature range improves their reliability and lifespan.

Protective measures: Consider implementing appropriate protection measures based on application requirements, such as overcurrent protection, over-temperature protection, and overvoltage protection. These measures help prevent damage to the inductors under abnormal conditions.

Perform reliability testing: Rigorous reliability testing is crucial once the design is completed. The testing process can include temperature testing, vibration testing, voltage stress testing, etc., to validate the performance and reliability of the inductors under different environments and operating conditions.

Verify inductor parameters: Validate key parameters of the inductors such as inductance, saturation current, frequency response, etc. Use suitable measurement equipment and methods to ensure that the inductor parameters align with expectations.

Consider environmental factors: Understand the environmental conditions in which the inductors will be operating and select appropriate materials and coatings. This provides additional protection and enhances the reliability of the inductors.

Document records: Maintain detailed documentation of the inductor design and testing processes, including parameters, layout, heat dissipation design, protective measures, etc. This facilitates traceability, troubleshooting, and serves as a reference for future designs.

By following these considerations and best practices, the performance and reliability of inductor applications can be improved, ensuring they meet the desired design requirements.