Production Process of Wirewound Inductors | Zxcompo

The production process of wirewound inductors is a precision engineering process that includes multiple steps.

The main steps are as follows:

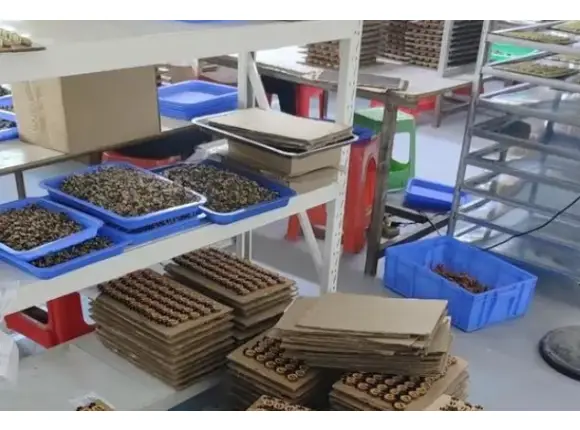

Step 1. Raw material procurement and inspection of wirewound inductors:

– Place orders to purchase raw materials such as magnetic cores and enameled wires based on the order quantity and BOM (bill of materials).

– After the raw materials are delivered to the company, IQC (Incoming Quality Control) will inspect the materials according to the inspection blueprint and inspection specifications.

– Qualified materials are notified to the warehouse for storage, and unqualified materials are fed back to the purchasing department for processing.

Step 2. Core processing and winding of wire-wound inductor:

– Select the appropriate magnetic core and enameled wire, and wind them according to the process requirements.

– When winding a coil, it may involve predicting parameters such as inductance, polarity and number of turns.

– The wound coil will be inspected. If it is NG (unqualified), it may need to be repaired or re-wound.

Step 3. Shaping, PIN cutting and coating of the wire wound inductor:

– According to the process requirements, shape the wound coil and cut the PIN length, or assemble it like BASE and wind the PIN.

– If necessary, coat the coil with Epoxy to fix the coil position and improve mechanical strength.

Step 4. Tin plating and testing of the PIN pin of the wirewound inductor:

– Tin plating the PIN feet to prevent oxidation and improve soldering quality.

– Use test equipment such as inductance meters to test the electrical performance of the inductor to ensure it meets specifications.

Step 5. Packaging and storage of wirewound inductors:

– The inductance products that have passed the test are packed into heaven and earth boxes or packaging boxes.

– Storage conditions must control temperature and humidity, usually requiring the temperature to be less than 40°C and the humidity to be less than 70%.

In addition, throughout the production process, the following issues need to be noted:

– Control of production environment, such as dust prevention and anti-static.

– Skill training for operators to ensure that every step meets process requirements.

– Regular maintenance and calibration of production equipment to ensure product consistency and quality.

– There may be specific production processes and precautions for different types of inductors, such as air-core coils and shielded inductors.

The above processes and precautions of Zxcompo will help manufacturers to efficiently and high-quality manufacture wire-wound inductors that meet the needs of electronic circuits.

Zxcompo is a reliable manufacturer of wirewound inductors designed to meet your specific needs. Contact us to request samples: sales@ZXcompo.com.