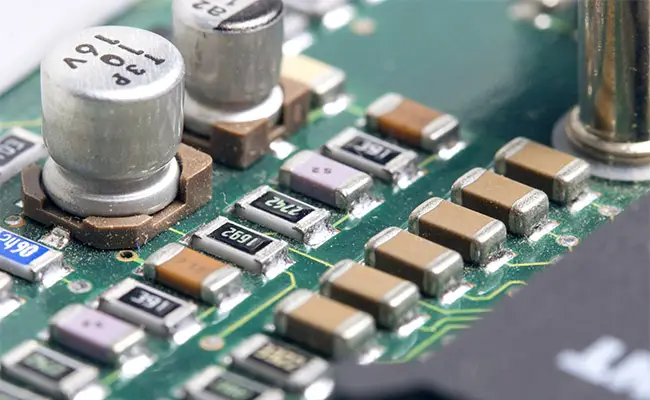

In water meters, inductors are usually used to detect the position and movement state of the dial rotor. Specifically, the inductor and the capacitor form an LC oscillation circuit. When the inductor is in the metal area, an inductive eddy current will be formed, resulting in increased power consumption and faster sine wave decay; when the inductor is in the non-metal area, there is no eddy current, and the sine wave decays relatively slowly.

By detecting the decay speed of the sine wave, the position of the dial rotor can be accurately identified. Then the position and number of dial turns can be determined to achieve the purpose of metering. The inductor in the water meter mainly works between the metal and non-metal areas of the dial rotor, and water consumption is measured by detecting the inductor eddy current.

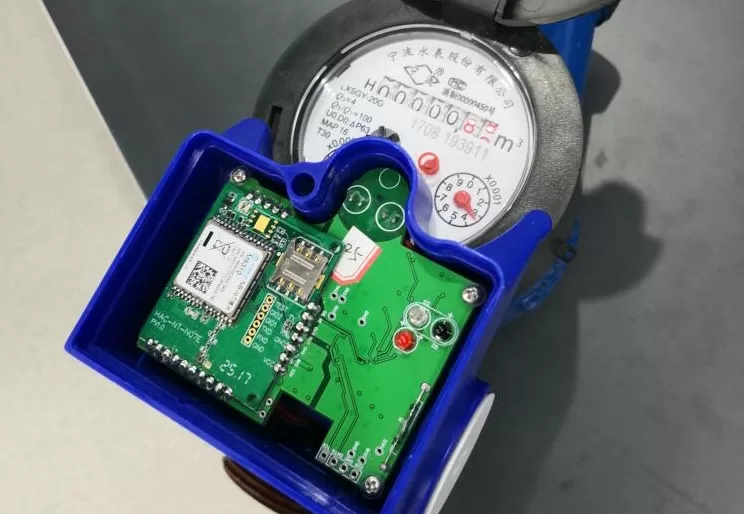

In addition, the sensing area of the water meter is generally set on the water meter, above the water outlet or on the side of the water meter. Users only need to stick the water card to these sensing areas to complete operations such as recharging and checking water consumption.

The inductor inside the water meter is usually located in the sensing area of the water meter, including the water meter body, above the water outlet and the side of the water meter.

The role of the inductor in the water meter:

The role of the inductor in the water meter is mainly to realize the functions of recharging the water meter and checking the water consumption through the sensing device. The user only needs to stick the water card on the sensing area of the water meter to complete the relevant operations.

This sensing device has requirements for the magnetism of the water card. If the water card is demagnetized, it cannot be sensed, so the water card needs to be protected.

The specific location of the sensor in the water meter:

1. On the water meter: The sensor may be installed directly on the surface of the water meter. The user only needs to stick the water card on the water meter to operate.

2. Above the water outlet: The sensor may also be set above the water outlet of the water meter. The user needs to stick the water card in this area to operate.

3. Side of the water meter: Some sensors may be installed on the side of the water meter. The user also needs to stick the water card here to operate.

Working principle of the sensor in the water meter:

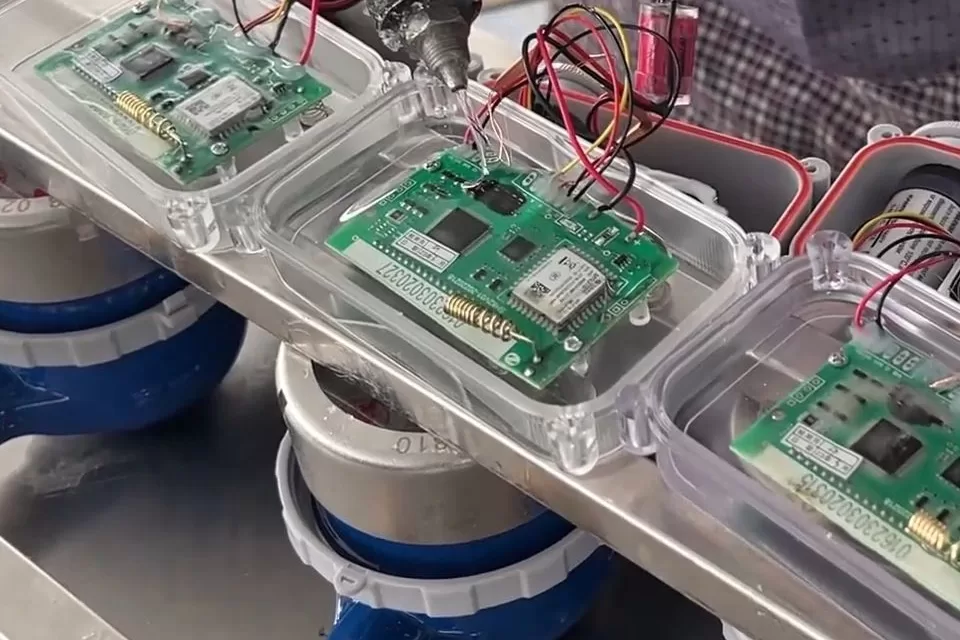

The working principle of the sensor in the water meter is that the water flow drives the impeller to rotate, and the rotation of the impeller is transmitted to the sensor through the gear transmission system. After the sensor senses the rotation signal, it records and monitors water consumption, water volume and other information through the management software. This design not only realizes the automatic billing function, but also reduces the trouble of manual meter reading and improves the efficiency of water management.

The working principle of electromagnetic induction water meter is based on Faraday’s law of electromagnetic induction.

When water flows through the electromagnetic water meter, the conductive liquid (usually tap water) in the water flow activates the sensor of the electromagnetic water meter, and the coil in the sensor changes the magnetic field, thereby generating an induced electromotive force.

According to Faraday’s law of electromagnetic induction, the induced electromotive force is proportional to the rate of change of the magnetic field, and the rate of change of the magnetic field is proportional to the volume and flow rate of the liquid flowing through, so the water flow rate can be indirectly measured by measuring the induced electromotive force.

The structure of the electromagnetic induction water meter mainly includes the following parts:

1. Sensor: The sensor is the core component of the electromagnetic water meter, which senses the water flow and generates the corresponding electromagnetic signal. The sensor is mainly composed of a coil, which is generally wound with copper wire and has good conductivity. It is used to sense the change in the magnetic field when the water flows through.

2. Metering component: The metering component is divided into a preamplifier and a measuring device. The preamplifier is used to adjust the water flow state, and the measuring device is used to measure the water flow and flow rate. The metering component usually consists of a turbine with blades and a metering chamber. The turbine is generally made of stainless steel, which has strong corrosion resistance and high mechanical strength.

3. Display and data processing components: including indicators, display screens and data processing chips, which are used to display and process relevant data of electromagnetic water meters. This part usually includes mechanical pointers and digital display screens, which can realize direct reading mode and intelligent mode.

4. Control components: The control components include manual operation switches, automatic control devices, etc., which are used to control the operating status of electromagnetic water meters.

5. Power supply components: The power supply components include batteries or external power supplies to provide the power required by electromagnetic water meters.

Advantages of Zxcompo Inductors

Zxcompo products include multilayer power inductors, wound surface mount inductors, and molded surface mount inductors for power and signal lines. A full range of passive electronic and magnetic components including inductors, capacitors, resistors, transformers, and filters are available. Our products are widely used in automotive, telecommunications, consumer electronics, and other fields. Each product is designed to achieve performance and maximize signal and power efficiency while saving space.

Other advantages include:

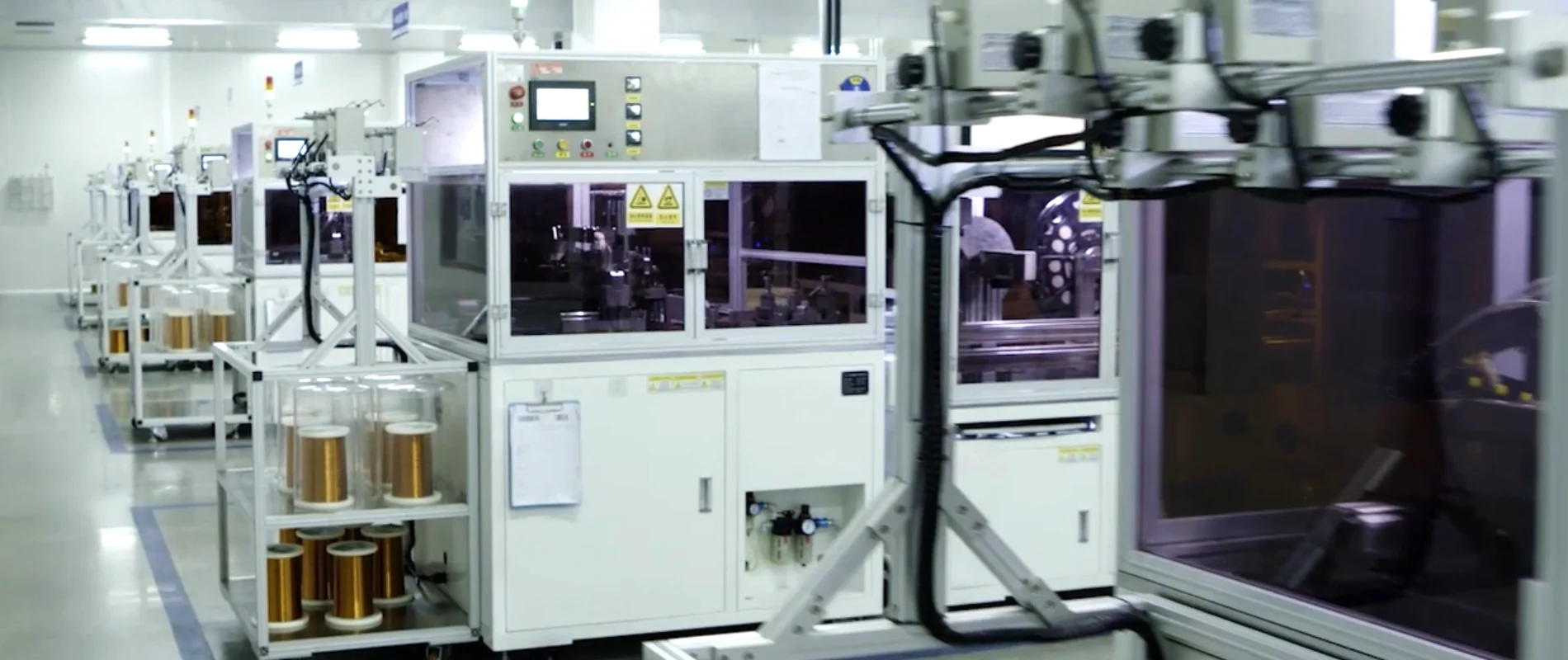

Fully automated manufacturing

High reliability AEC-Q200

ISO 9001 quality standards

RoHS compliant

REACH compliant

Why Choose Zxcompo?

Our company has more than 1,000 types of inductors and 15 years of experience in this field. It is a product that produces extremely low resistance over a wide frequency range. Zxcompo is widely recognized by a global technical team for designing, manufacturing, and providing high-quality, high-performance signal integrity and noise filtering solutions.

Zxcompo brand inductors, also known as coils or reactors, are passive electronic components that resist changes in the current flowing through them. Core material, winding type and geometry play a critical role in the performance of power inductors. Shipping worldwide. Simply contact us for samples: sales@ZXcompo.com.