The Definitions of Axial Components and Radial Components are as Follows:

Axial Components: The leads of axial components, such as axial lead capacitors, resistors, inductors, etc., are led out from both ends of the element, usually in the same direction as the center axis of the element.

Radial Components: The leads of radial components are led out from the same side of the element, usually perpendicular to the center axis of the component, such as radial lead capacitors, resistors, inductors, etc.

(★ If you want to learn more, please refer to this article: •Introduction to Zxcompo’s High-Power Radial Inductors)

The Main Difference Between the Two is the Direction of the Leads:

Axial Components: The leads are led out from both ends of the component, and their direction is consistent with its center axis.

Radial Components: The leads are led out from the same side of the component, and the direction is perpendicular to the center axis of the component.

Definition of Axial and Radial Packaging:

Axial packaging and radial packaging are both packaging forms of electronic components. The difference between the two lies in the arrangement of the pins of the components.

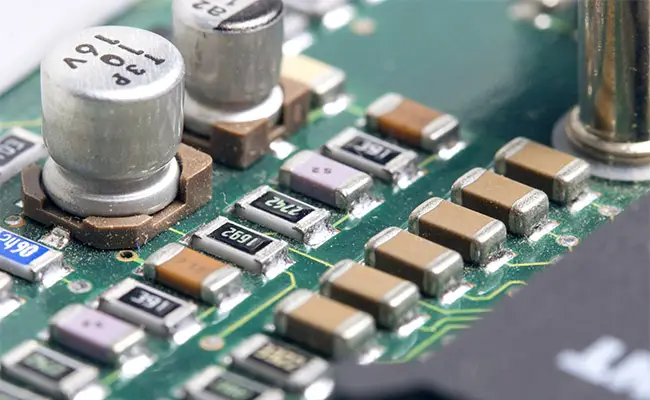

Axial Packaging: also known as “direct plug-in” packaging, the pins are arranged in a straight line, parallel to the axis of the component. Common axial components include diodes, triodes, electrolytic capacitors, resistors, etc. This packaging form is usually used in small circuit design, such as consumer electronics, computer motherboards, communication equipment, etc.

Radial Packaging: also known as “pin-type” packaging, the pins are circular or semicircular, and form a 90-degree angle with the radius of the component. Common radial components include electrolytic capacitors, inductors, etc. Radial components are mostly used in industrial mass production, such as televisions, audio equipment, etc.

Characteristics and Application Scenarios of Axial and Radial Components

Axial Components:

Small size: Due to the small pin spacing, axial components are usually small in size.

Welding method: Axial components can be automatically welded by a machine with high efficiency.

High packaging density: It can accommodate more components and is suitable for high-frequency circuits.

Application scenarios: Commonly used in small circuit designs with requirements on size and weight. In electronic components, it is used in scenarios where leads need to be drawn from both ends, such as integrated circuits, transistors, etc.

Radial Components:

Large volume: The pin spacing is large and the volume is relatively large.

Welding method: Manual welding is usually required.

Low packaging density: Fewer components are accommodated.

Application scenarios: Suitable for low-frequency circuits and industrial mass production. In electronic components, it is used in scenarios where leads need to be drawn from the same side, such as some surface mount components.

Development Trend

With the advancement of technology, especially the widespread application of SMT (surface mount technology), more and more components have shifted from axial packaging to SMT patch packaging. Although radial packaging is still widely used, in the new generation of electronic equipment and products, radial packaging components are used less and less, and SMT patch packaging components are more often used.

Advantages of Zxcompo Inductors

Zxcompo products include multilayer power inductors, wound surface mount inductors, and molded surface mount inductors for power and signal lines. A full range of passive electronic and magnetic components including inductors, capacitors, resistors, transformers, and filters are available. Our products are widely used in automotive, telecommunications, consumer electronics, and other fields. Each product is designed to achieve performance and maximize signal and power efficiency while saving space.

Other advantages include:

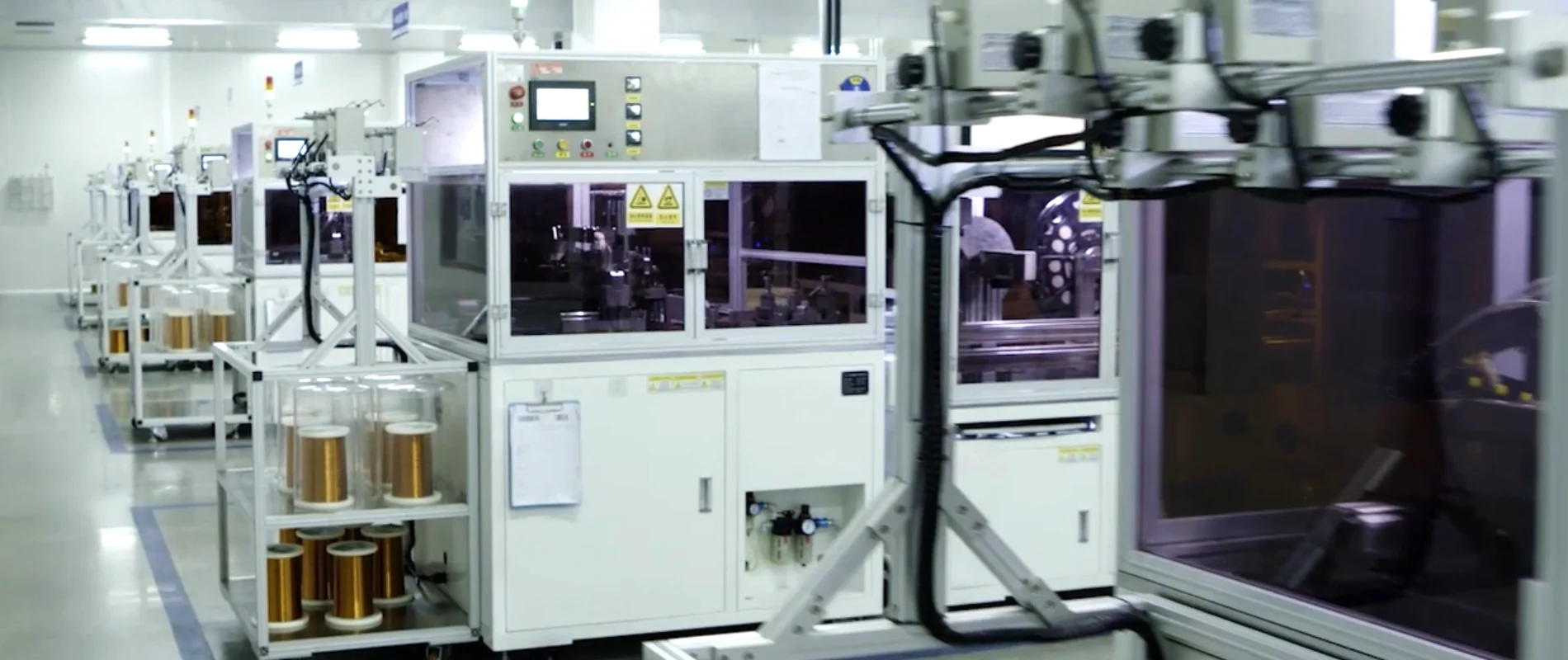

Fully automated manufacturing

High reliability AEC-Q200

ISO 9001 quality standards

RoHS compliant

REACH compliant

Why Choose Zxcompo?

Our company has more than 1,000 types of inductors and 15 years of experience in this field. It is a product that produces extremely low resistance over a wide frequency range. Zxcompo is widely recognized by a global technical team for designing, manufacturing, and providing high-quality, high-performance signal integrity and noise filtering solutions.

Zxcompo brand inductors, also known as coils or reactors, are passive electronic components that resist changes in the current flowing through them. Core material, winding type and geometry play a critical role in the performance of power inductors. Shipping worldwide. Simply contact us for samples: sales@ZXcompo.com.