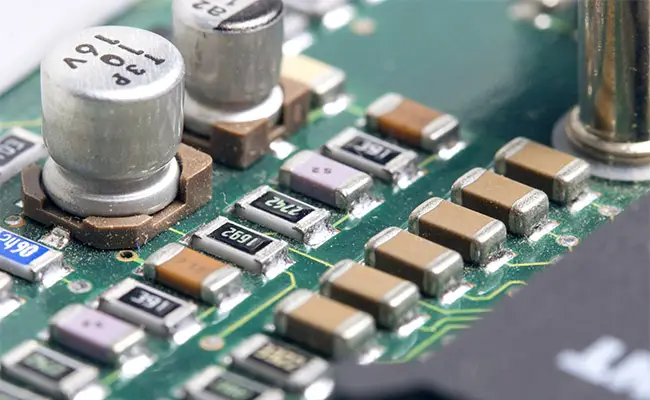

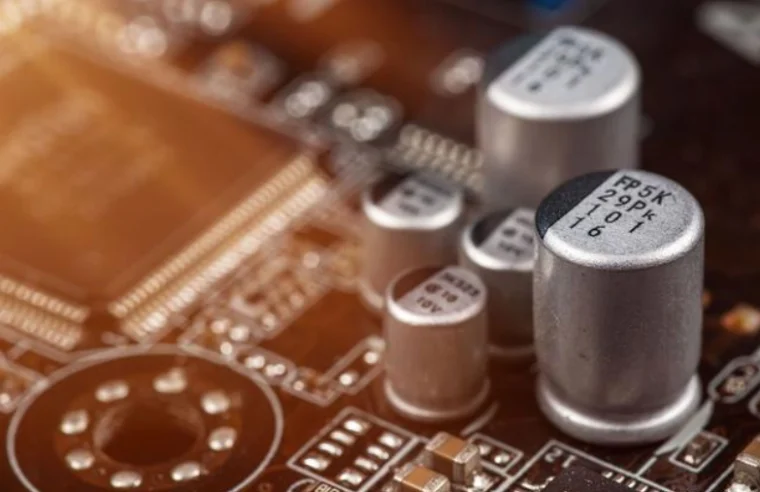

Aluminum electrolytic capacitors are capacitors that use aluminum foil as electrodes, form an aluminum oxide film on the electrode surface as a medium through an electrolytic oxidation process, and are encapsulated with an electrolyte and a shell. A layer of oxide film is formed on the positive electrode as a medium through DC voltage treatment. The characteristics of aluminum electrolytic capacitors are large capacity, but large leakage, poor stability, and positive and negative poles. They are suitable for power supply filtering or low-frequency circuits. When using, be sure to pay attention to the correct connection of the positive and negative poles, otherwise, it will cause damage to the capacitor.

The structure of aluminum electrolytic capacitors includes anode (aluminum tube), cathode aluminum layer, and electrolyte. The anode is composed of an aluminum tube, and the cathode is composed of an aluminum strip and oxide film. The paper between the two aluminum layers is soaked with electrolytes to ensure the normal operation of the capacitor. The application scenarios of aluminum electrolytic capacitors are mainly power supply filtering, low-frequency circuits, etc. Due to its large capacity but poor stability, it is not suitable for high-frequency circuits or occasions with high stability requirements.

Aluminum electrolytic capacitors have a wide range of uses, mainly including energy storage, filtering, compensation and circuit protection. Aluminum electrolytic capacitors play an important role in electronic circuits. They can pass AC and block DC, and have the functions of filtering, bypassing, coupling and fast charging and discharging. They are also small in size, have large storage capacity and are cost-effective.

Specifically, aluminum electrolytic capacitors have important applications in the following aspects:

1. DC isolation: The function is to prevent DC from passing through and allow AC to pass through.

2. Bypass (decoupling): Provide a low-impedance path for certain parallel components in the AC circuit.

3. Coupling: As a connection between two circuits, it allows AC signals to pass through and transmit to the next level circuit.

4. Filtering: Convert the sawtooth wave after rectification into a smooth pulsating wave, which is close to DC. Energy storage: Store electrical energy and release it when necessary.

5. Decoupling: Provide a low-impedance path for certain parallel components in the AC circuit to remove unnecessary AC signals.

6. Temperature compensation: Compensate for the impact of other components’ insufficient adaptability to temperature and improve the stability of the circuit.

7. Timing: Capacitors are used in conjunction with resistors to determine the time constant of the circuit.

8. Tuning: System tuning of frequency-related circuits such as mobile phones, radios, and televisions.

9. Energy storage: Store electrical energy and release it when necessary, such as camera flashes.

Characteristics of the Aluminum Electrolytic Capacitor Industry:

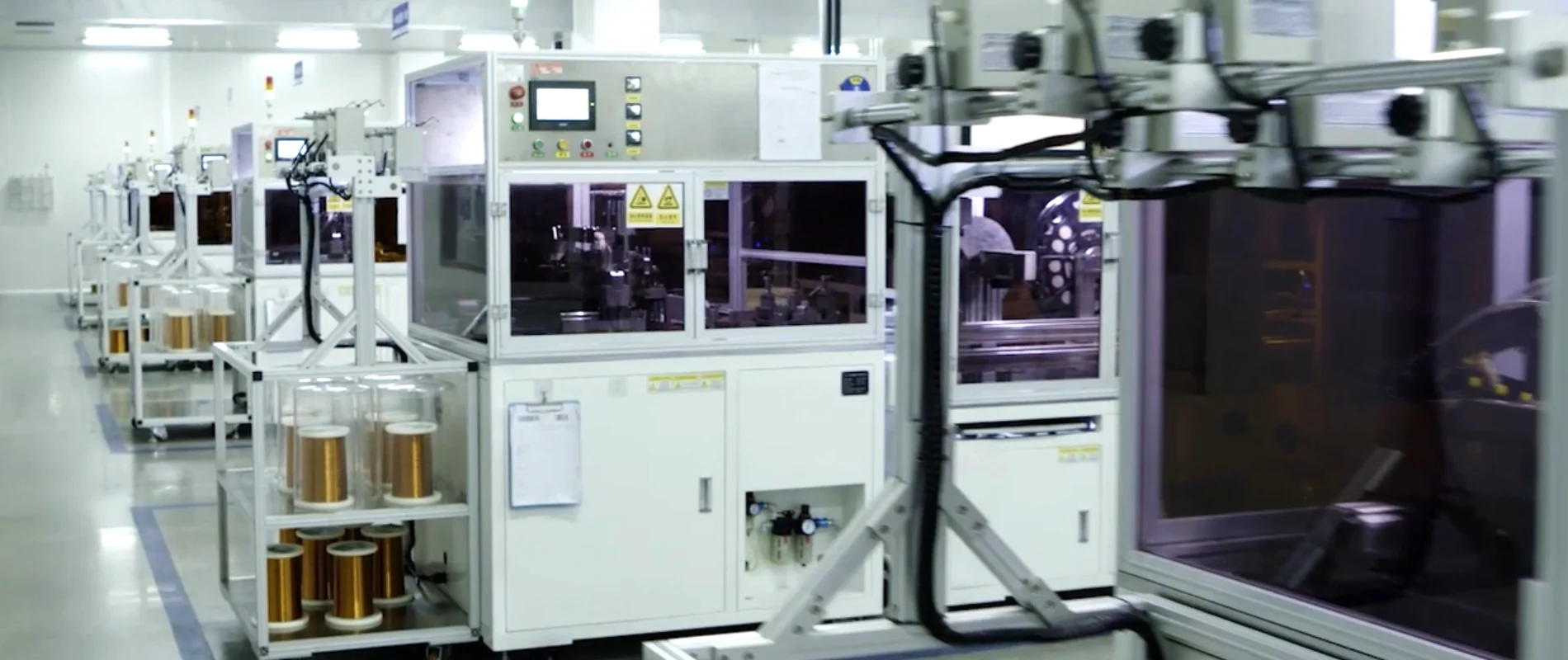

High technical content: The production of aluminum electrolytic capacitors involves precision machining, electrochemistry, materials science and other fields, and the technical threshold is relatively high. At the same time, with the continuous upgrading of electronic equipment, the performance requirements for aluminum electrolytic capacitors are getting higher and higher, and companies need to continuously invest in research and development to improve their technical level.

Wide market demand: As an important component of electronic components, the market demand for aluminum electrolytic capacitors is closely related to the development of the electronics industry. With the popularization of electronic products such as smartphones, tablets, and electric vehicles, the market demand for aluminum electrolytic capacitors continues to grow.

Strict environmental protection requirements: The production process of aluminum electrolytic capacitors involves the discharge of electrolytes and the treatment of waste. Companies need to strictly abide by environmental protection laws and regulations, increase environmental protection investment, and ensure environmental compliance during the production process.

Aluminum Electrolytic Capacitors are Mainly Classified as Follows in the Industry:

Aluminum electrolytic capacitors can be divided into many types according to different application scenarios and performance requirements.

Among them, they can be divided into small aluminum electrolytic capacitors and large aluminum electrolytic capacitors according to capacity; they can be divided into low-voltage aluminum electrolytic capacitors and high-voltage aluminum electrolytic capacitors according to voltage levels; they can be divided into organic electrolyte aluminum electrolytic capacitors and inorganic electrolyte aluminum electrolytic capacitors according to electrolyte types.

With the advancement of modern technology and the continuous improvement of capacitor performance, aluminum electrolytic capacitors, as an important part of electronic components, are widely used in consumer electronics, communication equipment, industrial automation, new energy vehicles and other fields, playing a key role in improving the performance and reliability of electronic equipment.

Advantages of Zxcompo Inductors

Zxcompo products include multilayer power inductors, wound surface mount inductors, and molded surface mount inductors for power and signal lines. A full range of passive electronic and magnetic components including inductors, capacitors, resistors, transformers, and filters are available. Our products are widely used in automotive, telecommunications, consumer electronics, and other fields. Each product is designed to achieve performance and maximize signal and power efficiency while saving space.

Other advantages include:

Fully automated manufacturing

High reliability AEC-Q200

ISO 9001 quality standards

RoHS compliant

REACH compliant

Why choose Zxcompo?

Our company has more than 1,000 types of inductors and 15 years of experience in this field. It is a product that produces extremely low resistance over a wide frequency range. Zxcompo is widely recognized by a global technical team for designing, manufacturing, and providing high-quality, high-performance signal integrity and noise filtering solutions.

Zxcompo brand inductors, also known as coils or reactors, are passive electronic components that resist changes in the current flowing through them. Core material, winding type and geometry play a critical role in the performance of power inductors. Shipping worldwide. Simply contact us for samples: sales@ZXcompo.com.