Capacitors are a type of component widely used in electronic circuits. SMD capacitors are a type of miniaturized capacitors that are widely used due to their small size, large capacity and high precision.

The working principle of SMD capacitors and SMD ceramic capacitors is based on the storage and release principle of electric field.

SMD capacitors, full name multilayer ceramic capacitors (MLCC), are a type of capacitor using surface mount technology (SMT) and are widely used in electronic circuits for energy storage, filtering, decoupling, resonance, etc.

Its working principle is the same as that of conventional capacitors, that is, an electric field is formed between two conductive plates to store charge.

SMD capacitors are usually made of ceramic dielectric diaphragms with printed electrodes in a dislocated stack. This structure allows it to have a small volume and weight while ensuring high density, so it is very suitable for the miniaturization and lightweight requirements of modern electronic equipment.

SMD ceramic capacitors, as a type of SMD capacitor, are characterized by a wide capacitance range, high precision, and good pressure and temperature stability.

Its internal structure consists of multilayer ceramic dielectrics and internal electrodes, and the capacitance is increased by dislocation. This capacitor uses multilayer ceramic materials as insulating media and realizes the function of capacitance by dislocation of electrodes. It has excellent electrical performance and stability.

In general, whether it is a chip capacitor or a chip ceramic capacitor, their working principle is based on the storage and release principle of the electric field. The electric field is formed between two conductive plates to store charge, thereby realizing the function of the capacitor.

Due to its special structure and material, the chip ceramic capacitor has higher precision and stability, and is suitable for application scenarios with high electrical performance requirements.

Among the many varieties of chip capacitors, the following four are common: multilayer ceramic chip capacitors, tantalum chip capacitors, aluminum chip capacitors and resistance reduction chip capacitors.

1. Multilayer Ceramic Chip Capacitors

Multilayer ceramic chip capacitors are excellent capacitors with the advantages of adjustable capacity, good stability and small size. The structure of multilayer ceramic chip capacitors is composed of multiple thin sheets of ceramic materials, and metal electrodes are coated between the layers. Because it is a multilayer structure and all electrodes are welded together, its internal series resistance is low, which can play a good role in high-frequency circuits. Multilayer ceramic chip capacitors are generally widely used in filters, couplers, amplifiers and other circuits.

2. Tantalum Chip Capacitors

Tantalum capacitors are capacitors made of tantalum metal as the main material. Due to its high density and good chemical stability, they are widely used in high-precision circuits. Tantalum chip capacitors are miniaturized tantalum capacitors with the advantages of small size, large capacity and good stability. The structure of tantalum chip capacitors is to evenly spray a layer of tantalum metal electrodes on a ceramic substrate to avoid leakage current and operating temperature changes of the capacitor, thereby improving the quality of the capacitor.

3. Aluminum Chip Capacitor

Aluminum chip capacitor is a high-capacity, low-ESR, low-output noise capacitor. Its structure consists of an aluminum electrode sheet coated on a ceramic substrate in the shape of a cuboid. Aluminum chip capacitors are generally widely used in power amplifiers, power supply circuits and other fields.

4. Low ESR Capacitor

A low ESR capacitor is a capacitor with extremely low ESR and loss tangent values. Its internal electrodes are made of conductive polymer materials, and a special structure is used between the electrodes and the patch to reduce the series resistance. Low ESR capacitors can play a better role in high-frequency circuits, such as power electronic components, power supplies, voltage stabilization circuits, data storage, communication systems and other fields.

In short, chip capacitors have the advantages of small size, large capacity and high precision, so they are widely used in various electronic devices. Multilayer ceramic chip capacitors, tantalum chip capacitors, aluminum chip capacitors, and resistance reduction chip capacitors are the four most common chip capacitors. It must be pointed out that although these four capacitors have their characteristics, they should be selected according to different circuit requirements in actual use.

How to Read the Model of SMD Capacitors and SMD Ceramic Capacitors:

SMD capacitors and SMD ceramic capacitors are both passive components. They have many similarities, such as the size and shape of the SMD capacitors are like cookies, and they are usually marked with model information on the bottom.

1. How to read the model of SMD capacitors

SMD capacitors usually have relevant model information printed on the bottom, as well as some parameter information, such as capacitance, rated voltage, accuracy, etc. The following are several common SMD capacitor models:

0805: The size is 2.0mm long, 1.25mm wide, and 0.8mm high.

1206: The size is 3.2mm long, 1.6mm wide, and 1.2mm high.

1210: The size is 3.2mm long, 2.5mm wide, and 1.0mm high.

1812: The size is 4.5mm long, 3.2mm wide, and 1.2mm high.

Generally speaking, the larger the model, the larger the size, and the larger the capacitance.

2. How to read the model of SMD ceramic capacitors

The logo and model information of SMD ceramic capacitors are usually also printed on the bottom. The following are common SMD ceramic capacitor models:

C1005: Indicates that the size of the component is 1.0mm long and 0.5mm wide.

C1608: Indicates that the size of the component is 1.6mm long and 0.8mm wide.

C2012: Indicates that the size of the component is 2.0mm long and 1.25mm wide.

C3216: Indicates that the size of the component is 3.2mm long and 1.6mm wide.

Like SMD capacitors, the larger the model, the larger the size, and the greater the capacitance.

(★ If you want to know more about chip capacitors, please refer to this article: •What are the characteristics of various capacitors and how to choose?)

Differences Between SMD Capacitors and SMD Ceramic Capacitors:

The main differences between SMD capacitors and SMD ceramic capacitors are materials, loss tangent, price, packaging, size, capacitance range, precision, lead effect and cost.

1. Material properties:

The materials of SMD capacitors and ceramic capacitors are different. Ceramic capacitors are a type of capacitor based on ceramics. The material is relatively brittle, but it has good high temperature resistance and stability. SMD capacitors are based on polymers and are not as fragile as ceramic capacitors, but their stability under external forces or high temperature environments is not as good as ceramic capacitors.

2. Loss tangent:

The loss tangent of SMD capacitors is usually below 0.005, while the loss tangent of SMD ceramic capacitors is usually above 0.01.

3. Package form:

Although the appearance of SMD capacitors and ceramic capacitors is basically the same, their packaging forms are different. Ceramic capacitors are generally exposed ceramic chips with relatively large volumes and no packaging on the surface, so they are more easily damaged. Chip capacitors are packaged through modern SMT technology. They are small in size and durable, and are more suitable for use in a variety of electronic products of various sizes.

4. Size:

Chip capacitors are usually very small, ranging from a few millimeters to tens of meters, while ceramic capacitors are larger, with a minimum size of 1 mm or even more.

5. Capacitance range:

The capacitance range of ceramic capacitors is very wide, generally from 1pF to hundreds of uF, while the capacitance range of chip capacitors is relatively narrow, usually between a few pF and a few uF.

6. Accuracy:

The accuracy of ceramic capacitors is very high, generally reaching 1% accuracy, while the accuracy of chip capacitors is relatively low, generally 5% or 10%.

7. Lead effect:

The lead effect of ceramic capacitors is relatively small because longer pins can be used, while the lead effect of chip capacitors is very small, and its lead is the metal lead on the back of the capacitor.

8. Cost:

Due to different production processes, the cost of ceramic capacitors is higher than that of chip capacitors. Because ceramic capacitors require the use of high-cost ceramic materials and manufacturing processes, while SMD capacitors can be quickly produced and packaged through modern production methods.

9. Application scenarios:

Due to the differences in materials and packaging forms, there are also differences in the application scenarios of ceramic capacitors and SMD capacitors. Ceramic capacitors are more suitable for high-performance circuit applications due to their high stability and reliability. SMD capacitors are suitable for use in electronic products that need to be in a small space due to their durability and small size.

These differences make SMD capacitors suitable for applications that are sensitive to size and weight, such as mobile devices, computer peripherals, etc., while ceramic capacitors are widely used in electronic circuits in harsh environments such as high frequency, high voltage, and high temperature due to their high precision and tolerance range.

In short, although SMD capacitors and ceramic capacitors have the same capacity, they are different in application scenarios, material properties, and packaging forms. We must choose the appropriate capacitor for application according to actual needs.

Uses of SMD Capacitors and SMD Ceramic Capacitors in Electronic Circuit Design:

SMD capacitors and SMD ceramic capacitors are widely used in electronic circuit design, mainly used for filtering, decoupling, matching, energy storage, etc.

Chip capacitors are capacitors that use polyester film as the dielectric. They have the characteristics of excellent insulation properties, high dielectric constant, and low loss. Due to the characteristics of SMD capacitors such as small size, high withstand voltage, and very low ESR at high-frequency resonance points, they are widely used in the mid-to-high frequency field. They are usually used for mid-to-high frequency (100 kHz to hundreds of MHz) filtering, such as power supply filtering, signal filtering, etc. …

In addition, chip capacitors can also remove high-frequency noise in the circuit, adjust signal amplitude and maintain signal stability, block DC in DC coupling circuits, and provide feedback capacitors for electric oscillators and resonant circuits, etc.

SMD ceramic capacitors are capacitors that use ceramic materials as dielectrics, and have the characteristics of excellent insulation performance, high dielectric constant, and low loss. At the same time, they also have good temperature characteristics, so that they can still maintain good performance in high temperature environments. Ceramic capacitors are widely used in electronic circuits in harsh environments such as high frequency, high voltage, and high temperature, such as communication equipment, computers, aerospace, and other fields.

SMD capacitors and SMD ceramic capacitors are widely used in electronic equipment, including but not limited to mobile phones, tablet computers, audio equipment, televisions and monitors, communication and network equipment, automotive electronics, etc. they are used for signal coupling filtering, power management, etc. in communications and network equipment; they are used for power management, voltage stabilization filtering, etc. in automotive electronics.

In addition, SMD capacitors, as energy storage elements, store charges in the form of electric field energy, which are used to absorb interference pulse signals in circuits and smooth surge currents. Its characteristics enable it to play a variety of roles in circuits, such as delay, absorption, filtering, resetting, and flipping.

In summary, SMD capacitors and SMD ceramic capacitors have a variety of uses in electronic circuit design, mainly involving filtering, decoupling matching, energy storage, etc. They are widely used in various electronic devices and systems, and are of great significance for improving the performance and reliability of circuits.

Finally, if you are looking for a supplier of magnetic components or passive electronic components. ZXcompo is a quality supplier of magnetic components and electronic components, compliant with ROHS, REACH, ISO 9001 quality standards. You can also order free test samples (inductors, capacitors, transformers, filters) from ZXcompo, our products are widely used in automotive, telecommunications, consumer electronics and other fields. And have 15 years of experience in this field. Whatever you need, just contact us to get a sample: sales@ZXcompo.com.

Advantages of Zxcompo Inductors

Zxcompo products include multilayer power inductors, wound surface mount inductors, and molded surface mount inductors for power and signal lines. A full range of passive electronic and magnetic components including inductors, capacitors, resistors, transformers, and filters are available. Our products are widely used in automotive, telecommunications, consumer electronics, and other fields. Each product is designed to achieve performance and maximize signal and power efficiency while saving space.

Other advantages include:

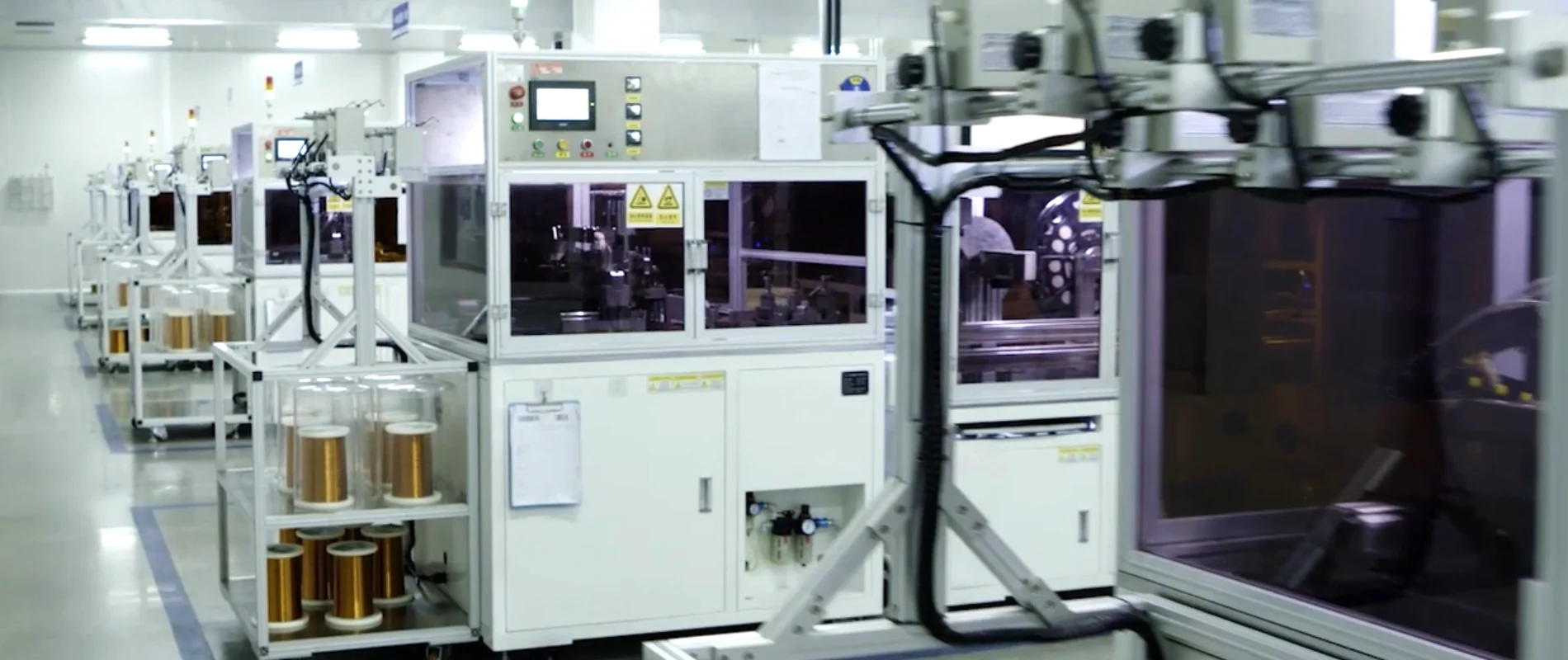

Fully automated manufacturing

High reliability AEC-Q200

ISO 9001 quality standards

RoHS compliant

REACH compliant

Why Choose Zxcompo?

Our company has more than 1,000 types of inductors and 15 years of experience in this field. It is a product that produces extremely low resistance over a wide frequency range. Zxcompo is widely recognized by a global technical team for designing, manufacturing, and providing high-quality, high-performance signal integrity and noise filtering solutions.

Zxcompo brand inductors, also known as coils or reactors, are passive electronic components that resist changes in the current flowing through them. Core material, winding type and geometry play a critical role in the performance of power inductors. Shipping worldwide. Simply contact us for samples: sales@ZXcompo.com.